When it comes to industrial manufacturing, we often hear about the final products—vehicles, machinery, or electronic systems. But behind every heavy-duty operation lies an unsung hero: the rugged industrial components that power and sustain the harsh environments of manufacturing plants. These components, though often overlooked, form the very foundation of the technology that keeps industries running. In this article, we’ll break down the essential rugged industrial components and why they’re critical in the modern manufacturing landscape. Among them, we’ll also mention the TAHJ408HD-1, a standout piece of hardware in the industrial tech realm.

Understanding the Role of Rugged Industrial Components

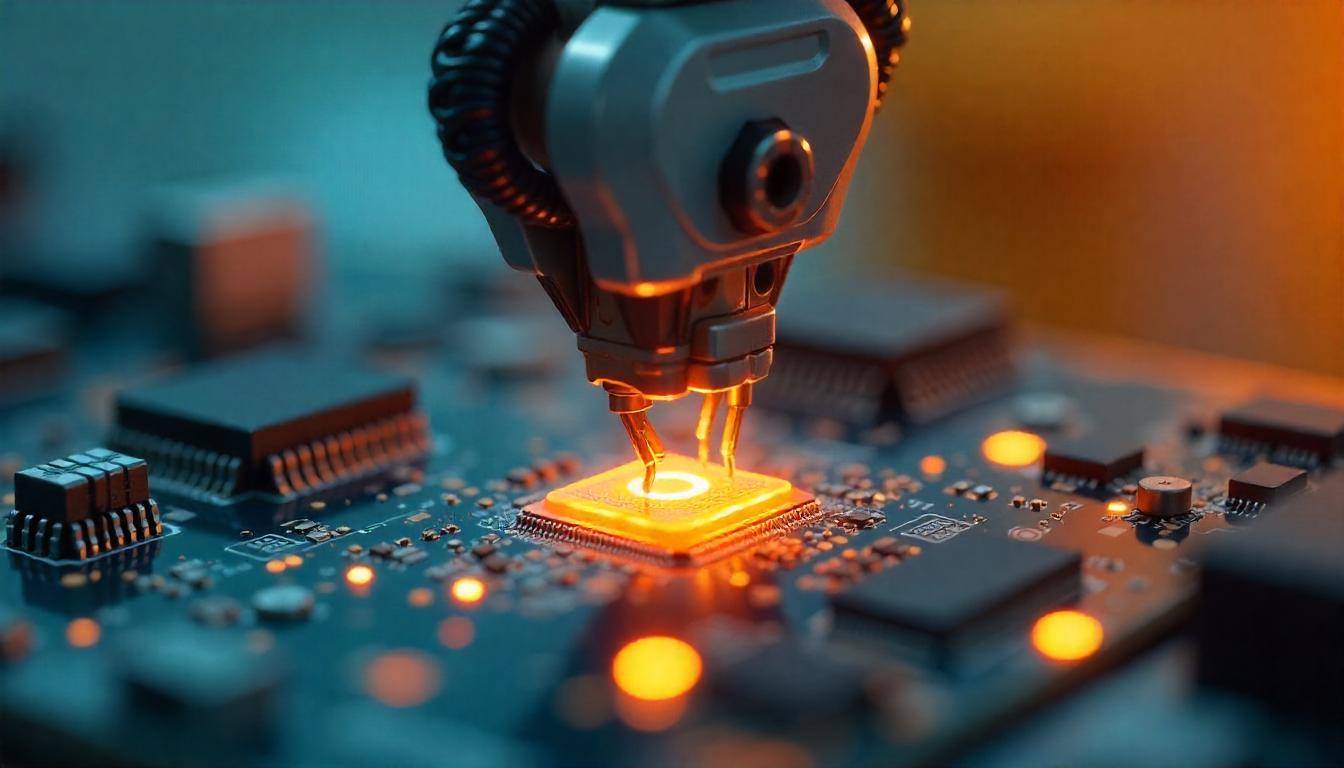

Rugged industrial components are designed to endure extreme conditions that would quickly disable or destroy standard off-the-shelf parts. Manufacturing environments are filled with factors like high temperatures, heavy vibrations, intense pressure, and exposure to corrosive substances, which all demand highly durable, precision-engineered components.

Key to the longevity and performance of machinery, these rugged components must be resistant to both physical wear and environmental stress. Their applications range from factory automation and robotics to heavy-duty vehicles and critical infrastructure.

Let’s take a closer look at the main categories of rugged components that play a pivotal role in industrial manufacturing.

1. Industrial Power Supplies

In the industrial sector, power supplies are vital to ensuring that equipment operates smoothly without interruption. Rugged power supplies are built to handle fluctuations in voltage, power surges, and harsh operating conditions like high temperatures and humidity.

These power supplies are often equipped with features like thermal protection, overcurrent protection, and EMI shielding to guarantee that the sensitive electronics in manufacturing equipment remain functional. Additionally, they are built for long-term reliability, reducing the need for frequent maintenance in tough environments.

Example: TAHJ408HD-1 Power Supply

A prime example of a rugged power supply in the industrial space is the TAHJ408HD-1. Built for durability in extreme conditions, this power supply offers impressive resilience to thermal extremes and vibration, making it a go-to option for systems requiring continuous uptime in unforgiving environments.

2. Industrial Connectors and Cable Assemblies

Connections are critical in any system, and industrial connectors are engineered to withstand everything from physical stress to chemical exposure. In addition to physical durability, industrial connectors must also support high-speed data transfer, high-power requirements, and the need for sealed connections to prevent ingress of dirt and moisture.

Cable assemblies that accompany these connectors are similarly ruggedized, often coated in protective materials such as Teflon or polyurethane, and reinforced with braided shields or armoring. These designs prevent wires from breaking or becoming short-circuited, ensuring reliable transmission in the most extreme conditions.

3. Heavy-Duty Actuators

Actuators are used in manufacturing systems to move mechanical parts in response to electrical signals, and they must be robust enough to handle repeated motion, heavy loads, and exposure to potentially harmful environments. Rugged actuators, whether electric, pneumatic, or hydraulic, are found in a variety of applications, from robotic arms in assembly lines to conveyors in material handling systems.

These actuators are typically rated to withstand harsh temperature ranges, physical impact, and excessive dust or liquids. For industries like aerospace, automotive, or mining, where systems operate in rugged, demanding environments, these actuators are indispensable.

4. Industrial Sensors and Measurement Tools

Sensors play a critical role in modern industrial systems by monitoring environmental conditions and providing data that allows for automation and optimization. Industrial sensors must be able to measure variables such as temperature, pressure, humidity, and motion without failure, even under high stress.

To cope with the environmental challenges of industrial settings, rugged sensors are designed to resist contamination, mechanical shock, and exposure to chemicals. These sensors must also meet certifications for hazardous areas, ensuring safe operation in explosive environments like oil refineries or chemical plants.

5. Robust Bearings and Bushings

Bearings and bushings are key components in nearly every type of mechanical system, supporting rotating parts and reducing friction. Industrial-grade bearings, unlike their consumer-grade counterparts, are designed to withstand the extreme forces and conditions found in heavy-duty machinery. These parts are made from high-strength metals or composites, and they are often sealed or lubricated to maintain smooth operation over long periods, even under high loads and temperatures.

In rugged industrial environments, the reliability of these parts is paramount, as their failure can lead to costly downtime. Bearings that are resistant to dirt, debris, or moisture intrusion are a crucial aspect of ensuring a production line remains operational.

6. Ruggedized Control Systems

Industrial control systems are responsible for automating manufacturing processes and ensuring precise operations. These systems need to operate reliably in tough environments, where temperature fluctuations, humidity, dust, and vibrations could otherwise cause failure. To prevent this, ruggedized control systems are built with reinforced enclosures, enhanced cooling mechanisms, and components that can tolerate high-stress environments.

For industries like automotive manufacturing or power generation, control systems must remain operational 24/7, even in the most demanding conditions. These systems often include PLCs (Programmable Logic Controllers), HMI (Human-Machine Interface) panels, and SCADA (Supervisory Control and Data Acquisition) systems, all designed for maximum resilience.

7. Industrial PCs and HMI Displays

Industrial PCs (IPCs) and HMI displays serve as the interface between operators and the machinery they monitor. These devices must be durable enough to withstand harsh environmental conditions such as extreme temperatures, moisture, and shock. In industrial environments, operators rely on these ruggedized systems to interact with machines, gather data, and manage operations.

Rugged industrial PCs are equipped with hardened casings, fanless designs, and IP-rated enclosures to protect against water and dust ingress. Meanwhile, HMI displays are engineered with anti-glare, impact-resistant touchscreens and shock-resistant mounts to ensure that operators can continue to manage operations even in rough conditions.

Conclusion: The Unsung Heroes of Heavy Industry

The reliability and performance of industrial manufacturing systems depend on components that are built to last through extreme conditions. Whether it’s the robust power supplies, durable actuators, or resilient control systems, these industrial components are essential for keeping production lines running without interruption.

While these components are often hidden from the spotlight, their role in the successful operation of industrial machinery cannot be overstated. The TAHJ408HD-1 power supply, for example, offers an ideal solution for systems requiring high durability, providing critical performance in environments that would challenge standard hardware.